Two-dimensional or 2D drawings cause a lack of shared understanding in construction projects. Various teams in construction projects must communicate and share information, including drawings, specifications, bills of quantities, schedules, and instructions. A graphical representation of what is to be built during the project is known as a construction drawing. There are different types of construction drawings: architectural, structural, plumbing and sanitary, finishing, etc. Construction drawings provide data about what will be built, the floor plans, sections, elevations, and various components depending on the type of drawing.

Construction drawings can also include information from other specialists, for example, structural engineers, HVAC, electrical, and fire safety. The amount of information and external collaboration depends on the project size. When building elements are prepared in 2D, human resources need to imagine a 3D visualization. 2D drawings are not enough to fulfill effective information sharing. No matter how accurate and precise they are, they'll never be as complete as the 3D simulation of the project. 2D drawings may cause misunderstanding and consequently increase unnecessary expenses in the project.

Needless to say, as the project's complexity grows, more materials are used, and also more data should be taken into account. In conclusion, 3D imagination of all the architectural, structural, and MEP elements becomes very difficult and impractical.

As a result, project costs and time increases, and legal disputes occur among project participants.

During the design process, the design team should analyze the design for the following criteria:

- Construction cost

- Energy consumption

- Lighting

- Space functions

- Aesthetic

- Constructability

- Construction schedule

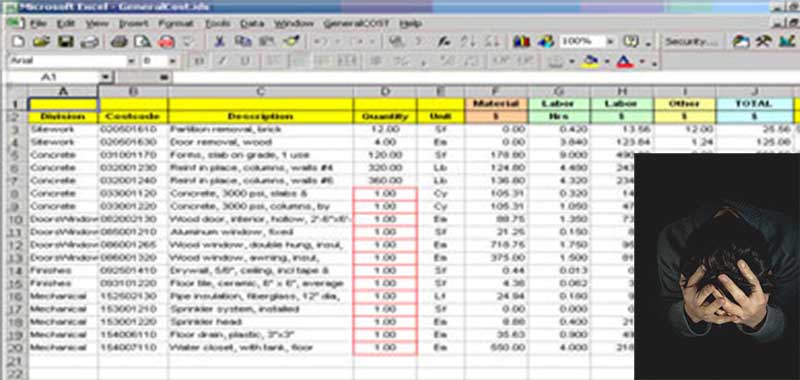

Analyzing 2D drawings needs a significant amount of time and money. For example, material quantities should be calculated manually to analyze the construction cost. On top of this, calculating material quantities manually increases the chance of error. This causes the design team and the owner to have less tendency to prepare alternative drawings and compare them against each other. If these analyses could be performed more effortlessly, they would have a tremendous impact on project time, cost, and quality.

One more drawback of 2D drawings is that it is not easy to change them. If one drawing (e.g., a plan) changes, other related drawings (e.g., sections) should be updated manually.

2D drawings cause problems in the bidding process as well. For liability reasons, architects and engineers prefer to provide fewer details in the drawings, which will lead to potential conflicts with the contractor in the future. The more clear, more precise, and more detailed the drawings are, the less additional costs are absorbed during the construction project. When the contractor is asked to work on a detail not included in the bidding documents, the contractor can easily claim more money.

In addition, contractors spend so much time and money to estimate the construction material quantities for cost-estimating purposes during the bidding process. Each contractor who participates in the bidding process forecasts the project's cost independently, and a contractor does not necessarily win the project. A contractor needs to participate in many bids to win one of them. Contractors usually have a bidding department in their office that regularly receives wages. In the US, each contractor, on average, spends one percent of the project budget on the bidding department.

After the bidding process and during the construction, inaccuracies in the drawings do not let the contractor order prefabricated materials from the manufacturers. Prefabricated materials are environmentally friendly. They do take less time than the traditional on-site construction method and lead to faster completion of the project. Prefabricated materials also reduce costs and increase project quality.

Many changes occur in the construction phase because of errors and ignoring details during the design process. These changes often happen after the contractor has built part of the project. Therefore, the contractor will be asked to demolish part of a previously built job and reconstruct it. For example, after completing the structure, they notice clashes between MEP and structure elements when they want to install MEP components. Clashes in construction projects occur when the parts or components are not appropriately coordinated, and as a result, conflict happens. Change orders cause legal disputes and increase project costs and duration.

After the construction phase, 2D as-built drawings are transferred to the owner. Then, the owner needs to spend significant time receiving the information, verifying its accuracy, and sending it to the facility management team. This process is prone to human error and requires a tremendous amount of time and money.

Building Information Modeling (BIM) is a process of creating and managing information for a built asset throughout its lifecycle—from planning and design to construction and operations. BIM definitely benefits every phase of the project lifecycle, even after the building is complete, although it is often associated with preconstruction. Building information modeling helps resolve many inefficiencies and problems that may arise during the construction process by allowing projects to be built virtually even before they are constructed physically. A vital part of the BIM modeling process is clash detection services. It eases identifying clashes and resolving them before starting construction. 3D BIM Model helps to resolve conflicts in less time through an automated approach. As a result, BIM services by BIM companies saves an enormous amount of time and money.

In summary, below are the problems with 2D drawings:

- 3D imagination of the project causes mistakes and conflicts between project participants.

- Design analysis and changing the design drawings require a significant amount of time and money.

- Lack of details in the bidding documents causes conflicts with the contractor during the construction phase.

- Quantity take-off is expensive for the contractor.

- Inaccuracies and conflicts in the design documents do not allow contractors to order prefabricated materials.

- Design changes during the construction phase result in legal disputes and increased project time and cost.

- Gathering and transferring as-built drawings and documents to the facility management team is time-consuming, error-prone, and costly.

If you found this article useful, we recommend you read our BIM services.